Pallet Wrapping Machine Hazards

Use caution when stepping on or walking off the turntable.

Pallet wrapping machine hazards. These are general safety guidelines to be used for a variety of stretch wrap machines. This ensures the employee will not have to bend at the waist to wrap the pallet. Orion semi automatics including the sentry lp lpd lpa hpd hpa and rtd rta are now setting the pace with only 2 3 week leadtimes for standard equipment. Drawing on nearly 25 years of industry experience handle it was created to manufacture floor mounted safety equipment dock equipment ergonomic equipment packaging equipment and other material handling products to serve the needs of industrial customers.

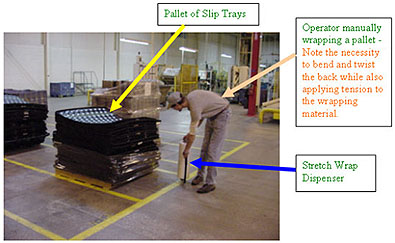

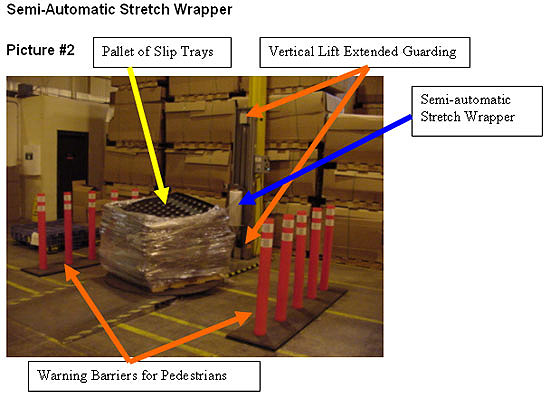

Hand wrapping is also connected with repetitive motion injuries one of the most common safety hazards in the warehouse. To ensure stretch wrapping equipment is safe it should be guarded or contained per 29 cfr 1910 212 a 3 ii general requirements of all machines. Only step on the turntable when power is off. Stretch wrapping case erecting.

Safer palletizing and automated stretch wrap machines as manufacturing processes become ever more sophisticated industrial safety standards are constantly being overhauled and updated to keep up with them. A stretch wrap machine eliminates these risks. Just because there is film around a pallet of products doesn t mean its unitized securely. If manual wrapping must be performed use rolls that weigh as little as possible to minimize the lifting hazard.

Use an automatic or semi automatic plastic wrapping machine with palletized product sitting on a turntable fig. Including secondary hazards that might harm. The past three years have been a particularly intense period of change with many forward thinking companies beginning to implement safer. Rotary arm and ring stretch wrapping machines clause 5 3 3 1 establishes the principle that the risk from the rotating film reel assembly on semi automatic machines of this type is acceptably low provided they are fitted with the specified safety protection devices however automatic machines are required to be guarded with a combination of.

And just because a box is sealed doesn t mean it will protect the products inside. Understand the fundamentals of stretch wrapping and case erecting and why it s so important to get it right. Stretch wrapping pallet unitizing machinery now only 2 to 3 week lead time for the industry s highest quality semi automatics. Clean machine once a day.

The machine will apply the force to tie the pallet together and there s no need for your employees to move the film rolls from place to place. Turn off the stretch wrap machine when finished.