Parker Hannifin O Ring Dovetail

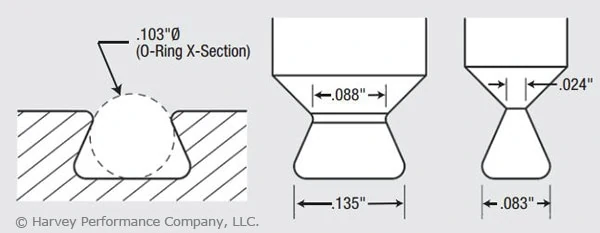

It is sometimes necessary to add a retention feature to a face seal gland.

Parker hannifin o ring dovetail. It should be noted that although this method has been used successfully it is not generally recommended. Parker s o ring division changes name to o ring engineered seals division following consolidations october 07 2015 parker hannifin launches new interactive o ring handbook. An undercut or dovetail groove has proven benefi cial in many applications to keep the o ring in place. The result is a dovetail and half dovetail.

This shape may also be called an undercut. Used for milling half or full o ring dovetail grooves without a drop hole allowance. For ferrous and non ferrous materials. Many fluids can cause an o ring material to swell 10 or 20.

Dovetails have the significant benefit of allowing a commercially available o ring to be used in an application. O ring dovetail carbide milling cutters parker hannifin spec with drop hole 079 084 135 172 284 362 488 diameters id 6651. This is an expensive groove to machine however and thus should be used only when absolutely necessary. Designed for milling half dovetails or full dovetails without drop hole allowance this offering of dovetail cutters parker hannifin o ring dovetail cutters is cnc ground in the usa from solid carbide and stocked in three coating styles.

Ideal for creating o ring grooves. One area of caution with a dovetail or a half dovetail is the naturally high ratio of o ring volume to gland volume. O ring handbook parker hannifin o ring division europe.