Pet Bottle Cap Manufacturing Process

Most caps you can feel them as a bit stiff are made of hdpe high density polyethylene.

Pet bottle cap manufacturing process. Diethylene glycol and acetaldehyde a large amount of acetaldehyde in pet can posibly affect the taste when you drink out of the cap bottle must. Some caps such as 2. Pet bottle production raw material. Polyethylene terephthalate pet pet is polymerized to create long molecular chains two impurities during this proces.

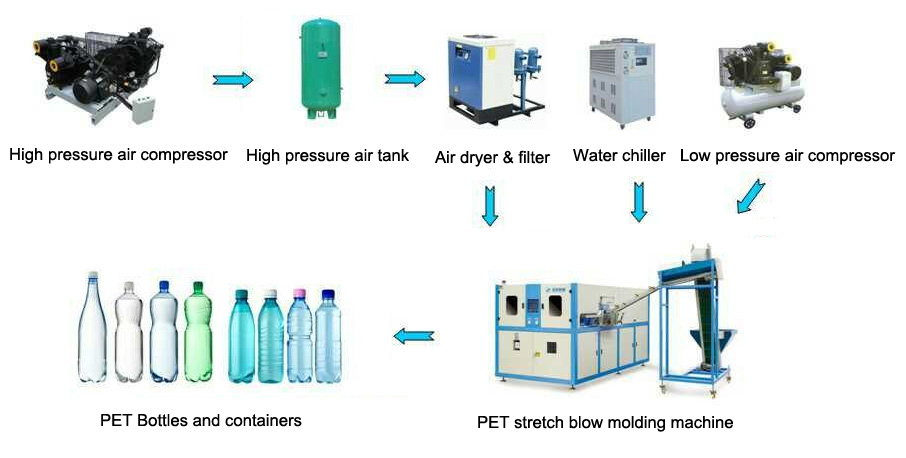

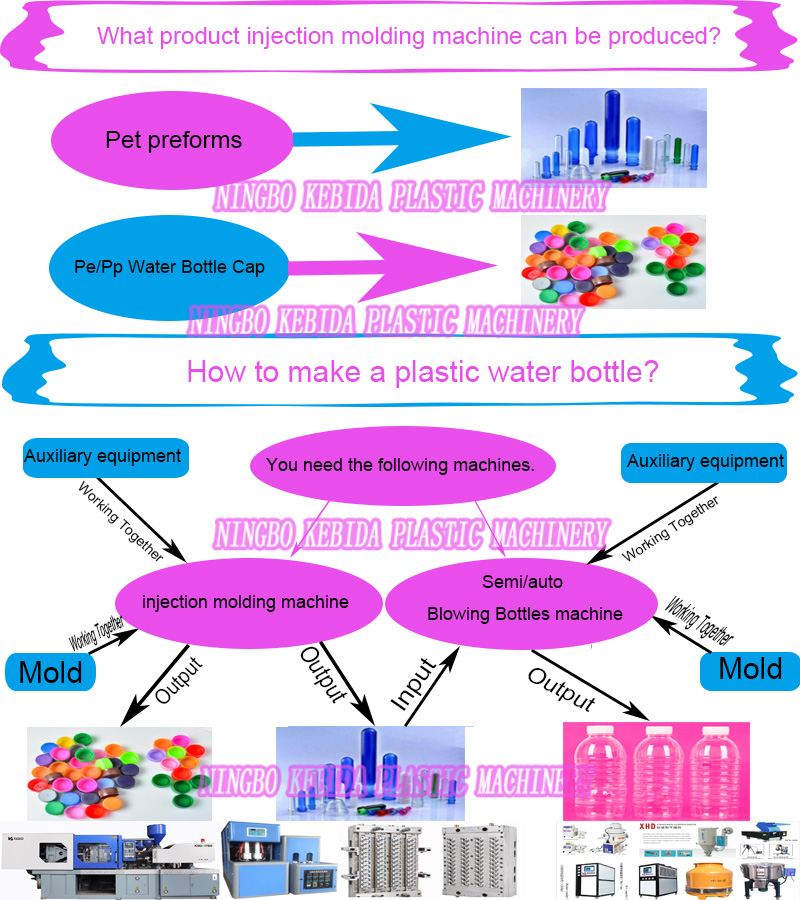

The manufacturing of pet bottles pet bottles are mainly manufactured in a two stage process. The raw material used in the manufacturing of pet bottles preforms is polyethylene terephthalate. These preforms already have the bottle cap threads and are small and easy to transport. Pet bottle production process.

Plastic bottle manufacturing process. The first stage of a typical 2 step reheat and blow machine rbm bottle manufacturing process is injection molding. Plastic pellets are plasticized in the barrel of an injection molding machine where the plastic is melted by heat and the shearing action of a feed screw. The pet granulate is first melted at about 280 c and processed into what are called preforms.