Powder Coating Tape Test

As with most people trying to obtain results using the tape test my frustration was with the variation in the method more so than the tape.

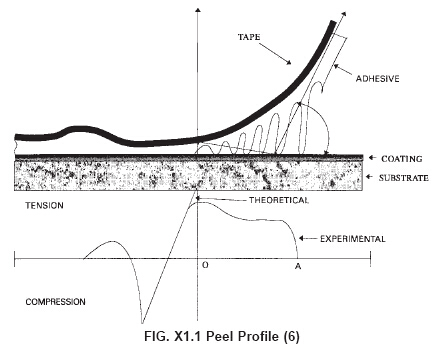

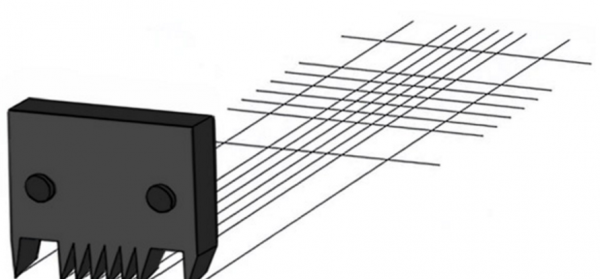

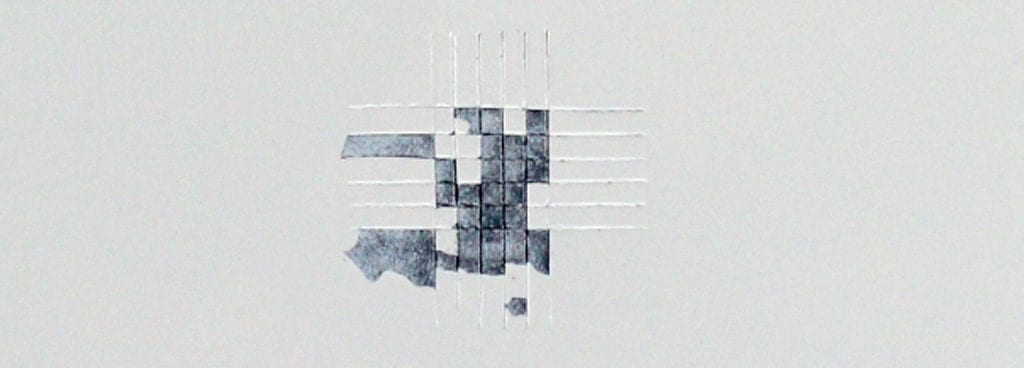

Powder coating tape test. Note 4 permacel p99 tape previously identified as suitable for this purpose was withdrawn from manufacture in july 2009. Pull the tape off aggressively and look at the tape and the part. In its simplest version a piece of adhesive tape is pressed against the paint film and the resistance to and degree of film removal observed when the tape is pulled off. It s performed by cutting a crosshatched grid pattern into the coating all the way down to the substrate.

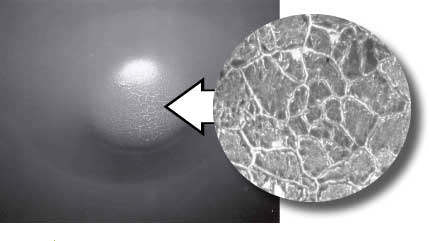

The most common areas to test for basic powder coating functionality are. The more paint that is removed the worse the overall grade would be. By far the most prevalent test for evaluating coating adhesion is the tape and peel test which has been used since the 1930 s. 5 chemical resistance test astm d1308 place approximately 10 drops of test solvent consisting of 95 by weight toluene and 5 by weight methal ethyl keytone on the surface of the coating.

That area is then judged to see if any paint was removed from the cross sections that were cut. The x cut tape test and the cross hatch tape test. Apply any sticky tape then remove slowly. There are two variants of this test.

I usually test 2 3 surface areas on the specimen to determine an overall average. This test is easy and a must for checking powder coating adhesion. If a square or two of coating is removed adhesion can be. 8 3 for test panels report the substrate employed the type of coating the method of cure and the environmental conditions at the time of testing.

A special pressure sensitive tape is then applied to the crosshatched area and then removed quickly at close to a 180 degree angle. Results should be no lifting of the cured powder between scribe lines. The crosshatch test is designed to test the adhesion of the powder coating to the metal substrate. Essential that tape from the same batch be used when tests are to be run in different laboratories.

The test is performed by making a series of cuts through the coating. No coating removal is a good pass. The x cut tape test is primarily intended for use at job sites. Last angle the tape at approximately 45 degrees then firmly holding the end of the tape give it a fast pull off the surface.

If this is not possible the test method should be used only for ranking a series of test coatings. Generally the pass fail is graded on a progressive scale. 8 4 if the adhesion strength of the tape has been determined in accordance with test methods d 1000 or d 3330 report the results with the adhesion rating s. Pressure sensitive tape is applied and removed over cuts made in the coating.

Allow to stand for 30 seconds. Tapes and adhesion testing for powder coating.