Precision Machine Leveling System

Level planes are created using the leveler rotational mount.

Precision machine leveling system. Several levels have prismatic bases which allow a higher degree of accuracy when measuring rounded surfaces. Starrett precision levels with calibration certificate. It is also a smart idea to check the level s accuracy by placing it on a surface that is already known to be level and see how it checks out. Such as machines which are subjected to significant.

Stadia are usually at ratios of 100 1 in which case one metre between the stadia marks on the levelling staff represents 100 metres from the target. An inaccurate level obviously will result in inaccurately levelled machines. It features an automatically rotating laser plane that is second in accuracy only to the l 740 ultra precision leveling laser. Thicker parts require our powerful flatmaster.

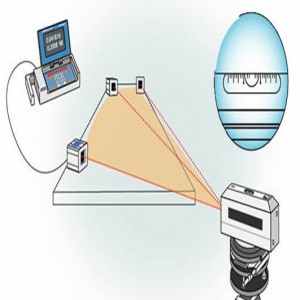

Using an electronic level system squareness and perpendicularity of a horizontal to a vertical surface such as a machine bed to the column is easy and quick figure 1. The laser is rotated between the 12 00 and the 6 00. From printing press units roll grinders and rolling roads to motors gearbox and prototype nacelle units we offer a full turnkey. In contrast our platemaster is the perfect machine for sheet metal parts and plates with a large surface area.

Wl les provide a system of installation of large or heavy equipment which requires a very rigid connection to their foundations and which also require very accurate alignment for satisfactory performance. We like to utilize the full travel of the machine tool axes to obtain a more accurate survey. Farrat precision levelling elements wl les are the ideal choice for the installation and levelling of precision and long bed machinery. Optical levelling employs an optical level which consists of a precision telescope with crosshairs and stadia marks the cross hairs are used to establish the level point on the target and the stadia allow range finding.

Hamar laser s l 730 precision leveling laser system is one of the most accurate and easy to use leveling surface flatness and straightness measurement system on the market today. Higher precision offers levels in a variety of different lengths and sensitivities. With a precision machined leveling surface and highly sensitive vial this level provides superior accuracy. The laser is now level and measurements can be made off it using the microgage receiver.

These levels come with a calibration certificate traceable to nist that states they ve passed a test for accuracy. Magnetic inserts come standard on some models which make leveling vertical application much easier for the operator. Precision machine equipment levelling using a combination of laser tracker instruments and over 30 years technical mechanical and metrology experience our experienced engineers carry out precision machine and equipment levelling across all industry sectors.